Project Details

DATE

November 21st, 2019

VEHICLE

2015 GMC Sierra 1500 Pickup

PROJECT TYPE

Repair

GMC Sierra 1500 Repair – Back on the Road

This repair was part of our Back On the Road 2019 program where we selected two local veterans to provide automotive services at no charge.

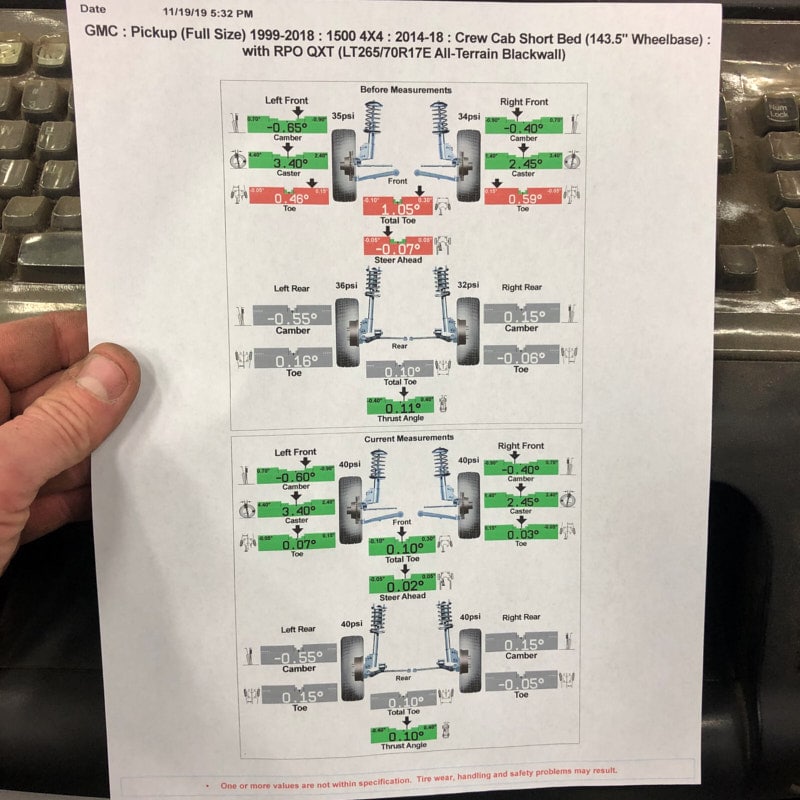

When Wyatt dropped off truck he request a couple things. First was there is a brake pulsation after driving for a little while. Second he wanted us to perform an Alignment, Wyatt stated that his tires are wearing funny. He also wanted us to check truck over for any maintenance needed. We put Wyatt in a loaner car and told him we would call when we were done.

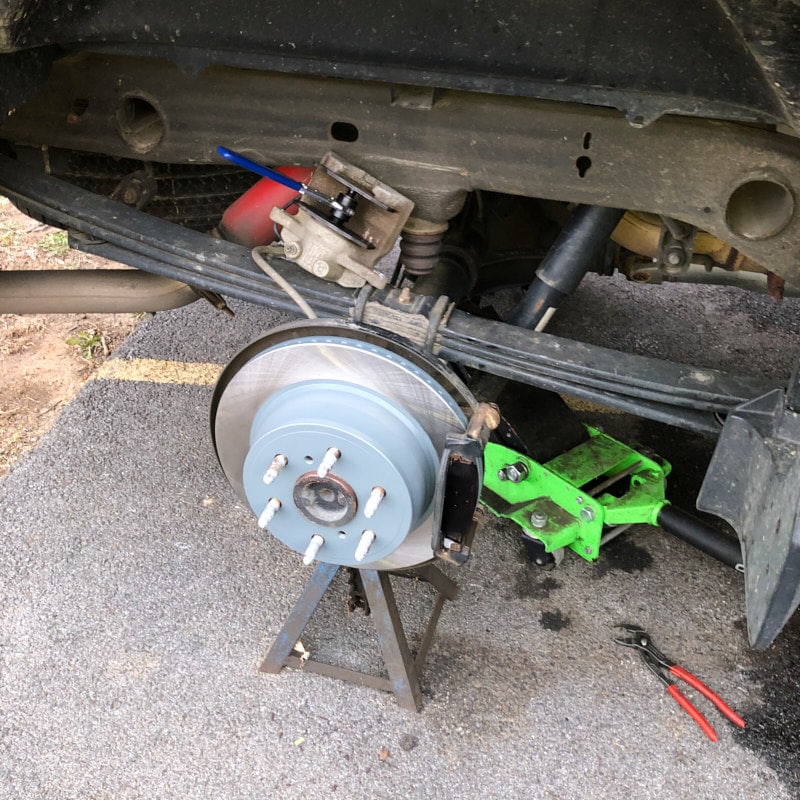

After out test drive we noticed there is something wrong with the brakes. We pulled all 4 tires to do an inspection. All four brake rotors have an extreme amount of rust build up and the brake pads are close enough where if we are taking apart to do rotors we should do the pads at the same time. Once all four rotors were removed, we cleaned up hub face and lubed. We also cleaned and adjusted the e-brake. We reassembled the brakes with all new rotors. The rotors we used have been painted and treated with a chemical to help prevent rust build up. After rotors we installed new GM brake pads front and rear. After brakes were completed, we flushed the brake fluid and replaced with new fluid.

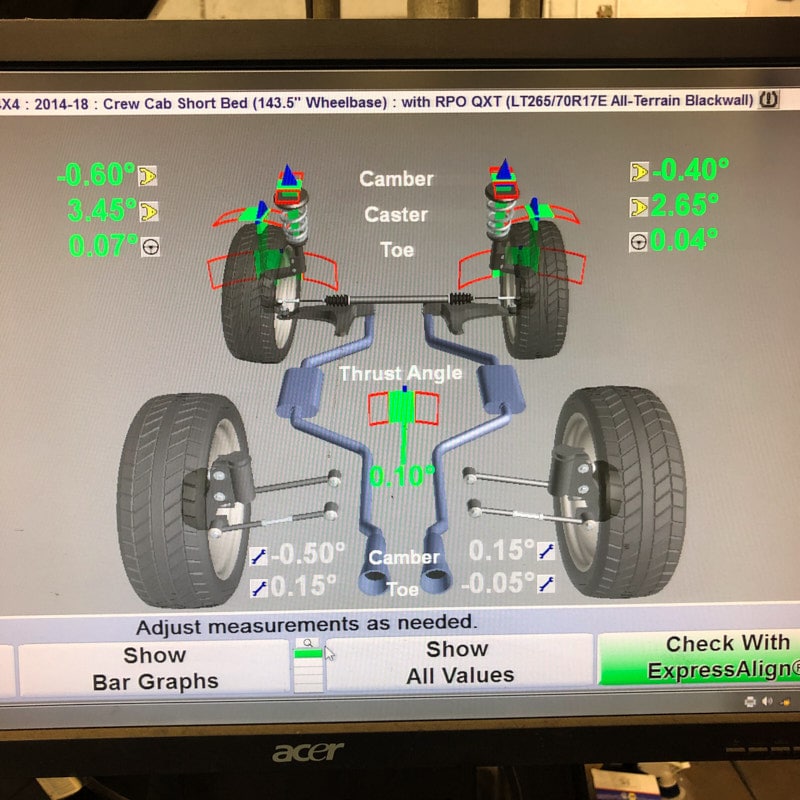

Next Wyatt’s truck went on the Alignment rack. All tire pressures were set to spec and alignment heads were installed and compensated. This gave us the readings we needed to correct any alignment issues the truck had. We test drove truck after brakes and alignment and now both major issues are now corrected.

We moved on to all maintenance items due for Wyatt’s Year, Make, Model, and Mileage. The brake fluid flush was performed during the first phase of repairs, so our list consist of Oil Change, Trans Fluid Exchange, and Service Mass Air Flow Sensor. The Air Filter was clean when we checked it.

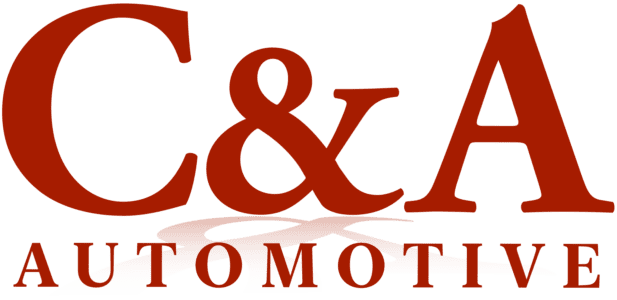

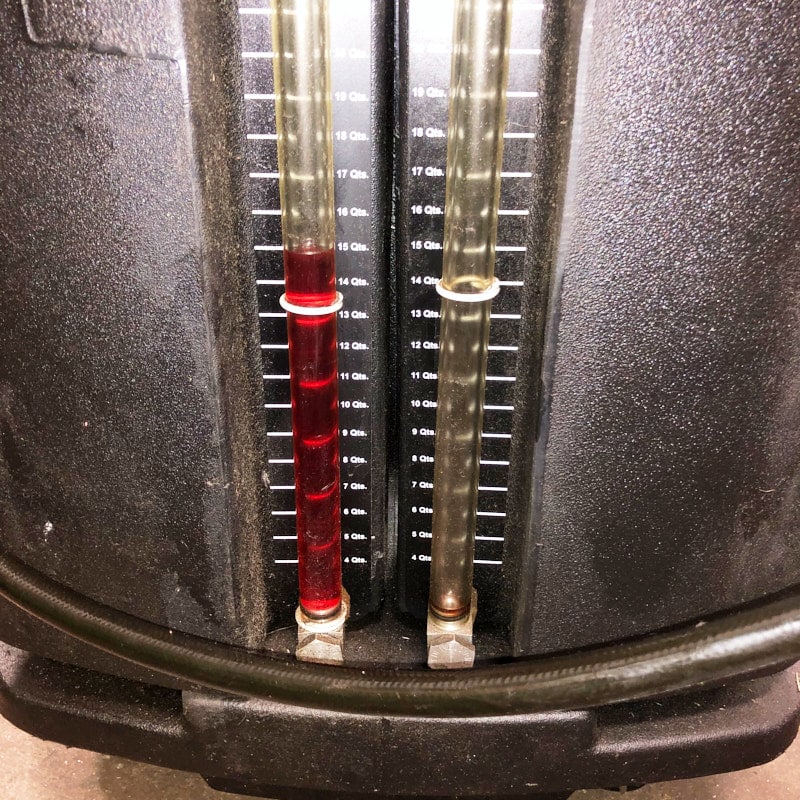

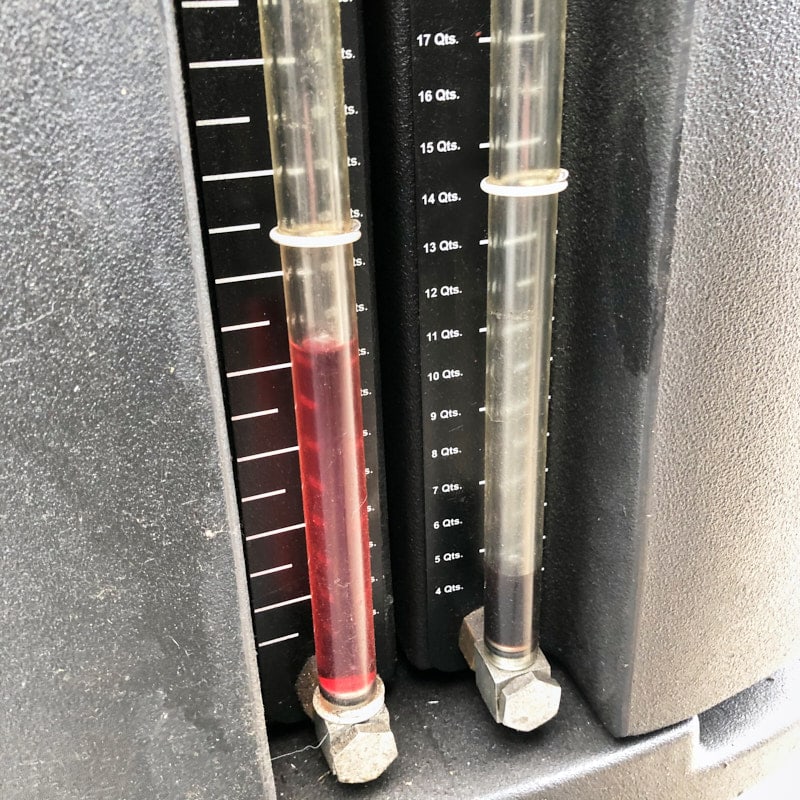

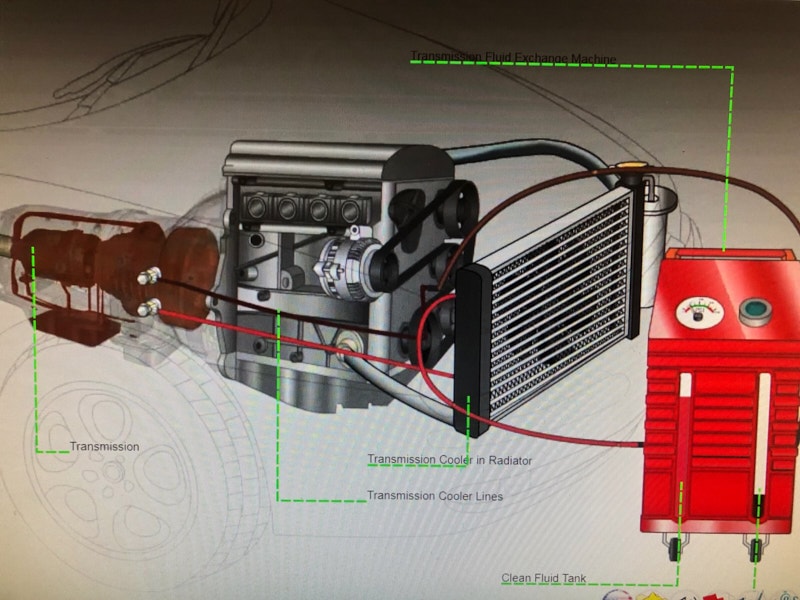

When we exchange Transmission Fluid we start by hooking a machine up to the transmission cooler lines in series. The machine is designed to accept dirty transmission fluid in one side, while pumping clean fluid out the other side. This is one of the best methods to insure we are exchanging all the fluid in the Transmission. The machine is filled with 14 quarts of new transmission fluid, hooked up to lines, and truck is started. When the truck is running the transmission pump is forcing the old fluid into machine. There is a pump in machine which pushes new fluid out the other side and into transmission. Once we start to see clean fluid being pumped back into machine, we know that all the old fluid is out of transmission. There is a lot of debate about how often this service should be performed. We feel it is best to do every 60K miles. Overheating is the number 1 cause of Transmission Failure. Dirty Fluid is the number 1 cause of Overheating.

Oil Change and Servicing the Mass Air Flow sensor was performed. Next it was time to wash truck and give it back to Wyatt.